|

|

A production scheduling method with negotiation and cooperation among customers |

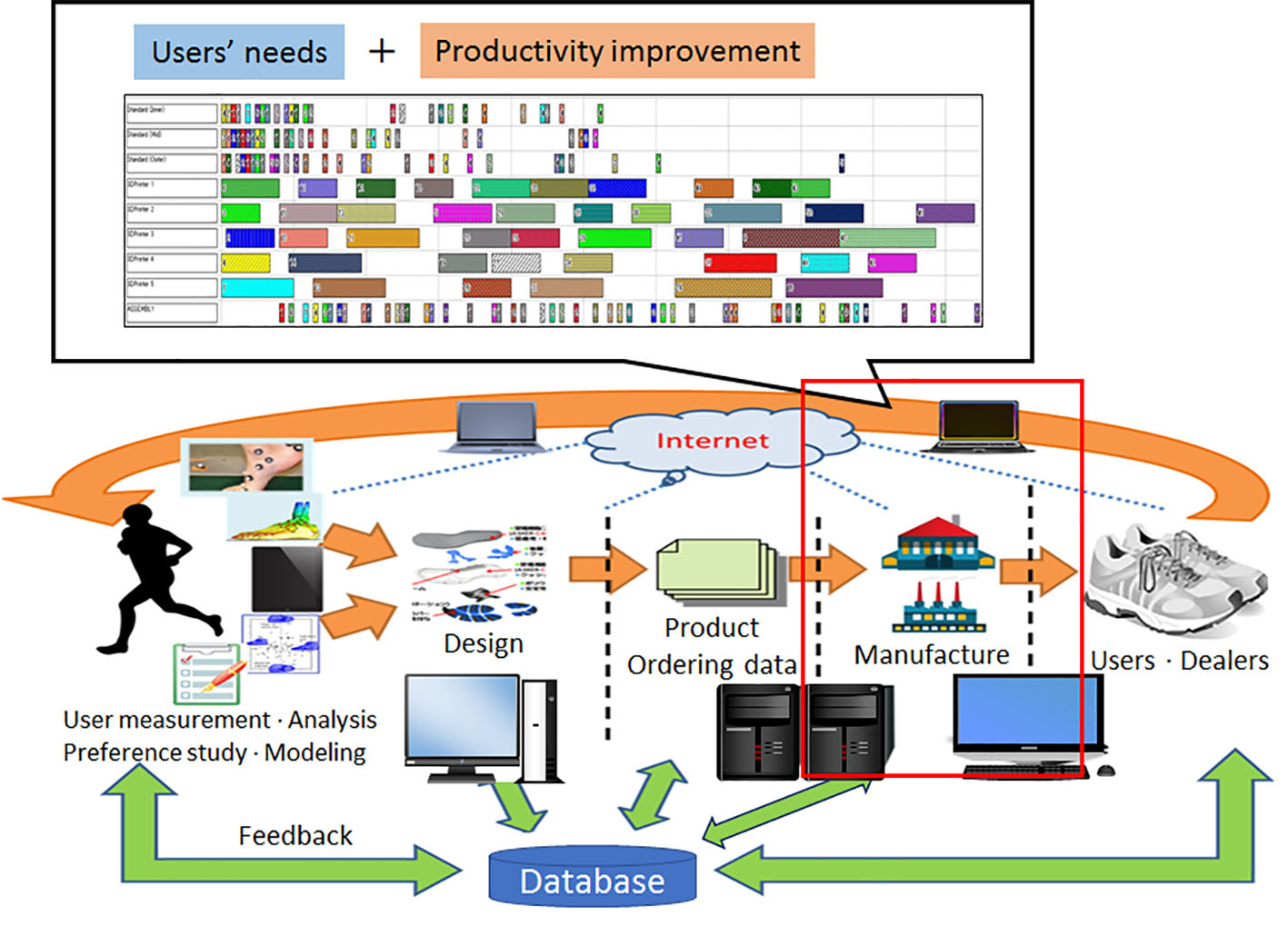

In recent years, mass customization, which is responding to diverse user needs by tailor-made and custom made and compatible

with price and production efficiency equivalent to mass production products, is attracting attention,

so production scheduling method to realize them is required.

Therefore, for build-to-order running shoes, we propose a production scheduling method applying a combinatorial auction

in the "planning phase" to make a long-term schedule, and applying a single auction in the "operational phase"

corresponding to the additional order. We propose this production scheduling method

and aim for useful schedule planning to realize mass customization.

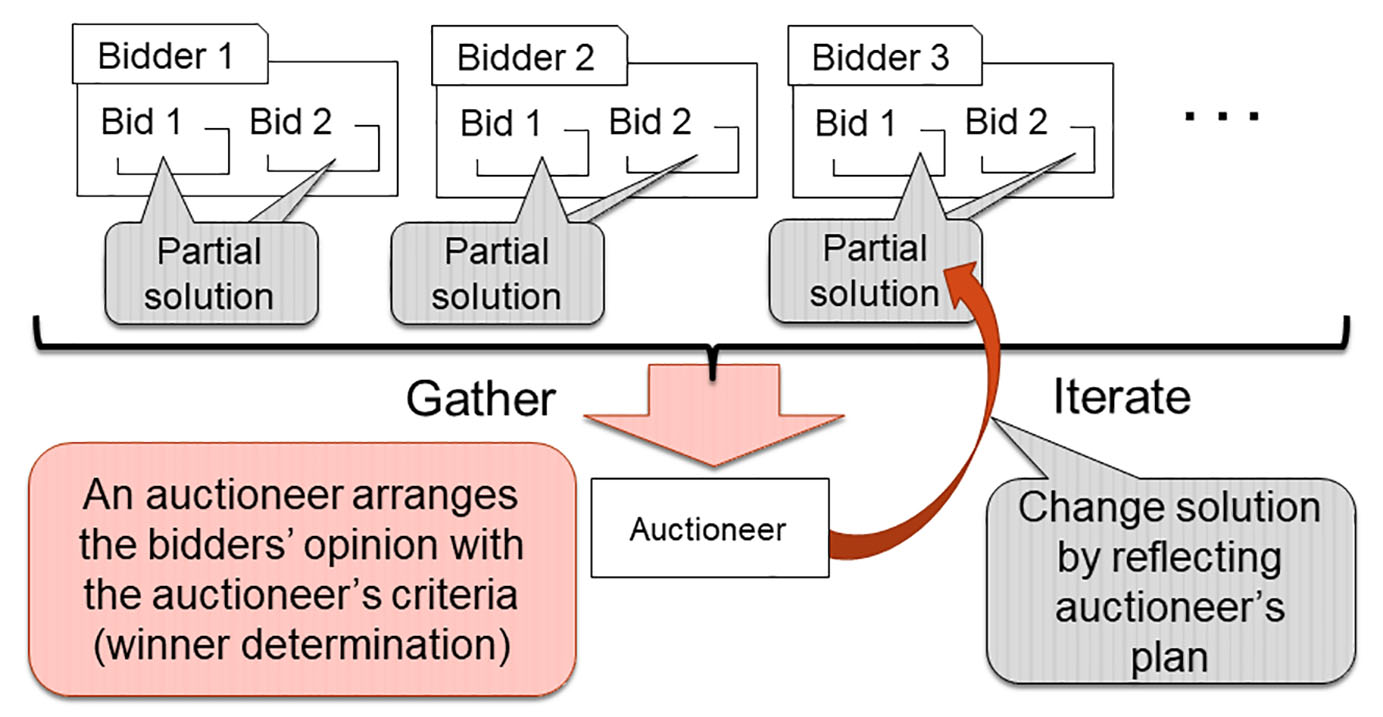

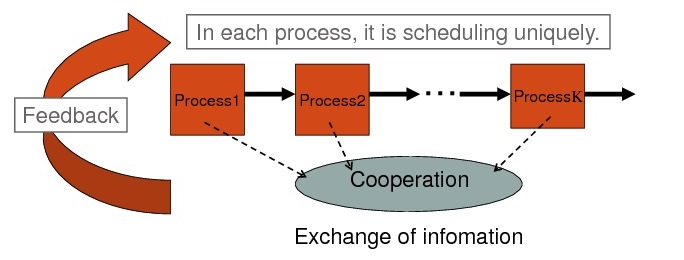

Schematic image of negotiation mechanism for making production schedule

|

A study on auction type production scheduling method for realization of mass customization

|

In recent years, mass customization, which is responding to diverse user needs by tailor-made and custom made and compatible

with price and production efficiency equivalent to mass production products, is attracting attention,

so production scheduling method to realize them is required.

Therefore, for build-to-order running shoes, we propose a production scheduling method applying a combinatorial auction

in the "planning phase" to make a long-term schedule, and applying a single auction in the "operational phase"

corresponding to the additional order. We propose this production scheduling method

and aim for useful schedule planning to realize mass customization.

Schema of tailor made-based design and manufacturing system

|

A study on production scheduling considering multiple planners with different schedule evaluation

|

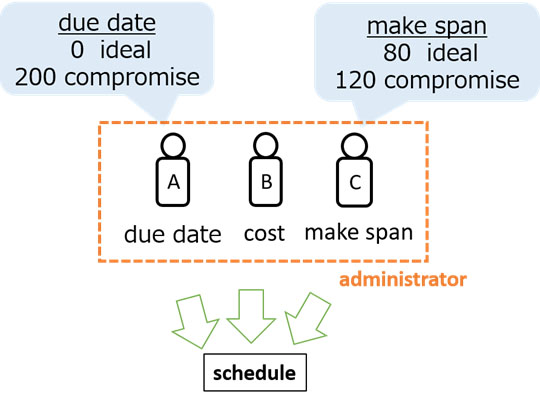

Usually, at the factory, a production schedule is created by adjustment by multiple planners while considering various factors such as the delivery date and the operation rate.

In this research, based on this current situation, we consider the model assuming three kinds of decision makers with different evaluation such as delayed delivery, overtime, outsourcing cost, and make span.

Using combination auctions that are effective for dealing with multiple goods, machine assignment,

worker assignment and work start time are determined at the same time and a production schedule which satisfies the evaluation criteria of all planners is formulated.

Schema of schedule planning using a combitonarial auction

considering with the multiple desicion

|

A robust optimization approach and characteristic analysis for two echelon distribution network with demand uncertainty

|

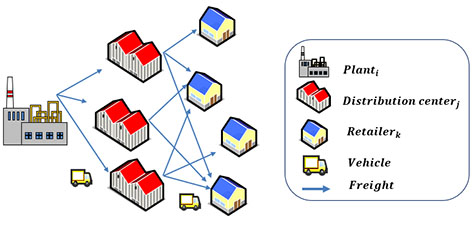

A mathematical model is developed to minimize total cost which consists of four type of cost in two-echelon supply network with product plants, distribution centers and retailers.

Demand from retailers are assumed to be uncertain, Robust optimization approach which assume uncertainty belongs to bounded interval is applied to cope with the uncertain problem.

Characteristic analysis is performed and its effectiveness is discussed.

Image of proposed two-echelon supply network and source of uncertainty

|

A Study on Naive Bayes based signature-driven Fault Detection for Production System in cyber-attack

|

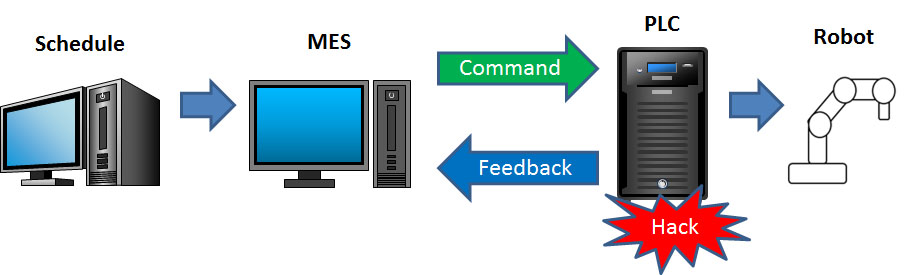

Nowadays, factory is facing security threat like cyber-attack.

It is not only causing huge losses, but also hard to detect.

This research proposes a fault detection for production system in cyber-attack, which is based on naive Bayes and fault signature.

An example of cyber-attack

|

Optimization Method Considering Human Factors for Cell Manufacturing System |

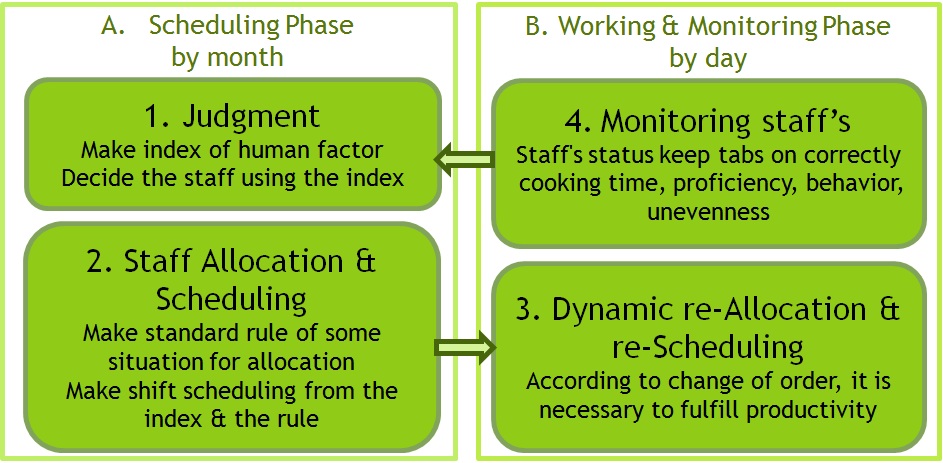

While manufacturing is increasingly automated and robotized, the labor-intensive cell manufacturing system still occupies an important position in the manufacturing industry. Since operator skills greatly affect the productivity in labor-intensive cells, effective skill training of operators is required. On the other hand, in order to cross-train operators, more detailed planning for training is needed. In this research, an optimization method for operator-allocation focusing on the progress of operator skills and productivity is proposed.

Optimization process that takes into account the human factor in the cell production system

|

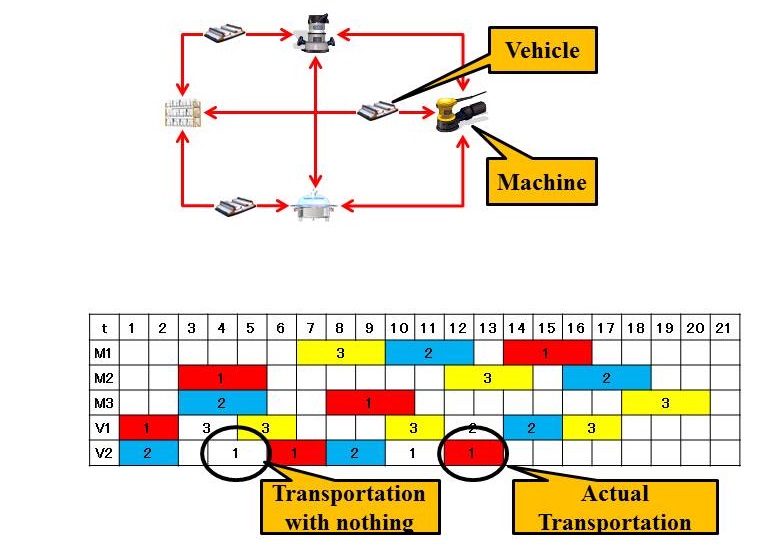

A Research on the Production Scheduling Method with Transportation by Using Lagrangian Decomposition and Coordination |

Efficient transportation among machines is an important topic in flexible manufacturing systems. Therefore, in this research the Lagrangian decomposition and coordination method (LDC) and the heuristic method are applied to the manufacturing scheduling problem which contains transportation among machines in the aim of high-efficient transportation and optimized scheduling.

Production scheduling which takes into account the transport

|

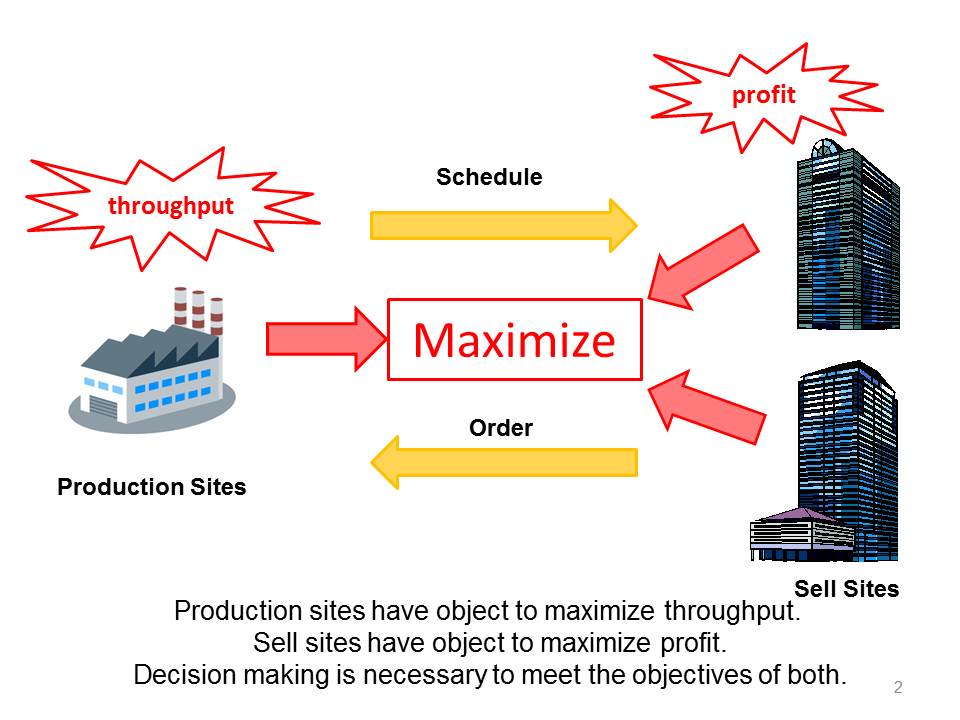

An Application of Combinatorial Auction to Global Sales-Production Management integrated Production Systems |

The number of companies having production/sales sites all over the world is increasing. The optimal scheduling method, which can ensure the profits at all sites, is hence required. The combinatorial auction method is introduced to optimize the production scheduling problems for the global supply chain in this research.

Configuration of global production system

|

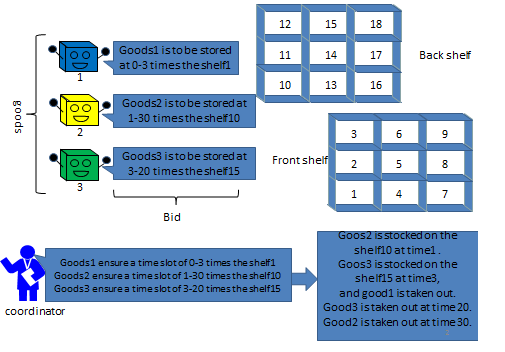

Optimal Operation Methodology for Automated Storage/retrieval System in Warehouse |

Due to the recent growing importance of efficient operation of product distribution, automated storage/retrieval systems have been commonly employed. Double-deep storage systems, which save a lot of storage space, attract attention because of the needs for cost reduction and the increase in larger-scale distribution centers. The aim of this study is to simultaneously optimize the storage assignment and the storage/retrieval scheduling for automated double-deep storage systems by using combinational auction which can effectively allocate multiple items.

Optimal operation system of automated warehouse with a combination auction

|

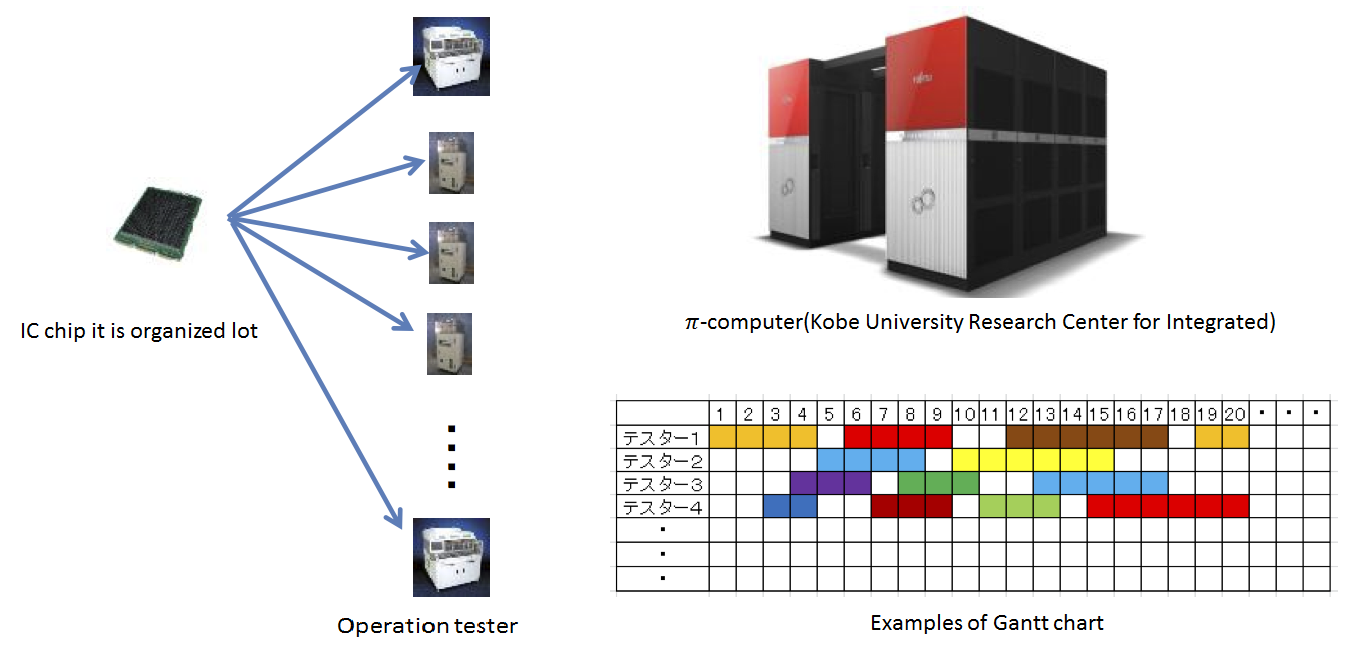

Fast Solution of Operation Test Schedule in Semiconductor Manufacturing by Massively Parallel Computation |

Nowadays, when it comes to semiconductor manufacturing, the hardness of the operation test of IC-chips is increasing because of its denser integration and wider variety. In this research we consider the distribution of chips in lot-formation, that is, we decide when and to which tester we should distribute chips in order to make an optimal schedule. When we take real scale problem into consideration, the calculation will become large, so we are attempting to perform massively parallel computation in order to solve this problem faster and effectively.

Massively parallel optimized scheduling of semiconductor test process

|

Cost Minimizing Scheduling with considering Lot Formation and Set-up in Flexible Flowshop. |

In the manufacturing system with lot formation, various decisions have to be made referring to lot formation, machine to be used, processing order, etc. And also, in the factories with such systems, manufacturing process needs many incidental /adjustment works, causing higher manufacturing cost. The aim of this research is to minimize the cost by optimal scheduling considering lot formation and setup in large-scaled flexible flowshop.

The decomposition process scheduling by Lagrangian Decomposition and Coordition Method

|

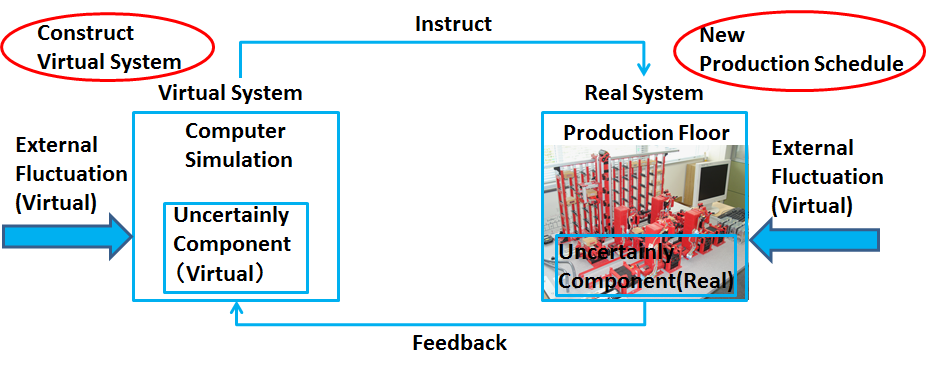

Real-Virtual Fusion Manufacturing System |

In Flexible Manufacturing System, there is a great deal of external fluctuation (order change or delayed delivery of materials) and uncertain incidents (machine trouble or process tardiness). Therefore, it is difficult to execute real production according to the schedule planned in advance. In this study, a new concept based on Cyber Physical Systems (CPS), named Real-Virtual Fusion Manufacturing System(RVF-MS), is newly proposed, which aims to adaptively and effectively deal with both external and internal fluctuations by realizing a fusion between real production floor(real system) and manufacturing model(virtual system). The proposed RVF-MS is verified by using a model plant.

Real-Virtual fusion production scheduling

|

|